Introduction

In the ever-evolving realm of aerospace engineering, the trajectory of progress is unmistakably marked by the transformative influence of fiberglass composites. As we delve into the intricacies of advanced materials, this article serves as a comprehensive exploration of the pivotal role played by fiberglass composites in shaping the present and future of aircraft construction. From the historical evolution of composites to their applications in fuselage design, engine systems, and interior components, we unravel the multidimensional facets that contribute to the unparalleled strength, efficiency, and innovation introduced by these materials. As we navigate through the advantages, challenges, and future prospects, join us on a journey through the dynamic landscape of fiberglass composites, unlocking the secrets that propel aerospace engineering into new frontiers of possibility.

I. Evolution of Aerospace Composites

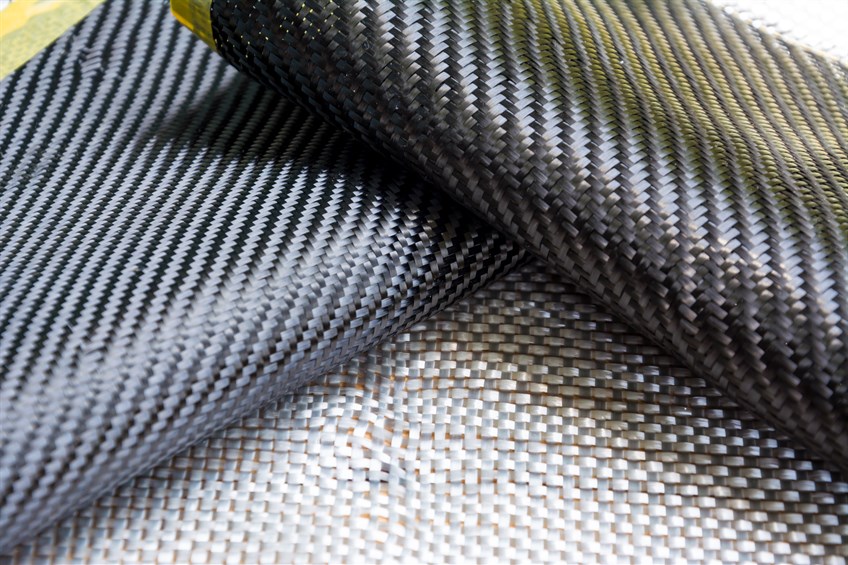

Over time, aerospace composites, marrying reinforcing fibers and matrix materials, have reshaped aircraft construction, ushering in strength, efficiency, and innovation. Ongoing research focuses on enhancing fiber materials and embracing innovations like three-dimensional weaving.

II. Lightweight Materials in Aircraft Design

Advanced composites, surpassing traditional metal alloys, offer unparalleled strength, weight reduction, and corrosion resistance. Future innovations include three-dimensional weaving, smart composites, and emerging materials like carbon nanotubes.

III. Unveiling Fiberglass Composites

Exploring advanced composites reveals the transformative impact of fiberglass composites. These materials, incorporating reinforcing fibers and matrix materials, outperform traditional alloys. Fiber types, weaves, prepregs, and matrix materials play key roles in achieving strength, flexibility, and durability.

IV. Applications in Aerospace

A. Structural Efficiency

Cutting-edge composites, combining reinforcing fibers and matrix materials, achieve exceptional structural efficiency in diverse aerospace applications.

B. Interior Components and Cabin Design

Advanced composites play a vital role in structural and interior components, showcasing superiority over traditional materials. Fiber types, weaves, and matrix materials guide material selection for strength, durability, and thermal resistance.

C. Engine and Propulsion Systems

Combining reinforcing fibers and polymer resin, these composites offer significant weight savings, driving efficiency and innovation in aircraft manufacturing.

V. Advantages of Fiberglass Composites

A. Weight Reduction and Fuel Efficiency

Fiberglass composites contribute significantly to the longevity, safety, and efficiency of aircraft, promising future innovations in three-dimensional weaving and emerging materials.

B. Durability and Resistance to Corrosion

Enhanced durability and resistance to corrosion are pivotal attributes, shaping the future of aerospace with innovative designs.

C. Design Flexibility and Performance Capabilities

The complex arrangement of reinforcing fibers and matrix materials enhances strength and efficiency, marking a transformative shift in aerospace.

VI. Challenges and Limitations

Advanced composites, while offering unparalleled benefits, introduce manufacturing complexities, cost considerations, and challenges in fiber selection, fabric forms, and matrix materials.

VII. Maintenance and Repair Considerations

Distinctive challenges in assessing and addressing delamination, impact damage, and environmental degradation of composite structures.

VIII. Regulatory and Safety Standards

Pivotal role of regulatory and safety standards in ensuring compliance with industry guidelines for advanced composites.

IX. Future Prospects and Innovations

Ongoing research and development in fiberglass composite technology, surpassing traditional alloys in weight, strength, and performance, with a focus on sustainability and bio-based composites.

Conclusion:

In conclusion, the profound impact of fiberglass composites on aerospace engineering is undeniable, representing a paradigm shift in materials science and aircraft design. The journey through the evolution of composites, their applications, advantages, and challenges underscores their transformative role in achieving strength, efficiency, and innovation. As we navigate the intricate web of fiber types, weaves, and matrix materials, it becomes evident that fiberglass composites have not merely redefined the structural landscape of aircraft but have also paved the way for future advancements.

The advantages of weight reduction, enhanced durability, and resistance to corrosion contribute not only to the efficiency of individual flights but also to the broader goals of sustainability and fuel economy. Despite the challenges posed by manufacturing complexities and cost considerations, ongoing research and development hold the promise of overcoming these obstacles, propelling the aerospace industry into new realms of possibility.

As we stand at the intersection of history and innovation, fiberglass composites emerge as the linchpin in the ongoing narrative of aerospace engineering. The journey does not end here; it extends into the future, where three-dimensional weaving, next-gen fibers, and bio-based composites promise to reshape the very fabric of aviation. With a keen eye on regulatory standards and safety considerations, the aerospace industry is poised to continue its trajectory toward unprecedented achievements, guided by the strength and versatility that fiberglass composites bring to the forefront. In essence, the future of aerospace is intricately woven with the fibers of innovation, and fiberglass composites stand as the unyielding threads binding it all together.

For more information on aerospace composites, visit Aerospheres. Explore related articles: Flying High with Composites: Your Essential Guide to Aircraft Composites, Sticky Solutions: Navigating the World of Aircraft Tapes, Composite Products Catalog, G0904 Composite Sealant, BMS9-3 TYDCL7ST120-38 Composite Material, and Peel Ply B100-1000..

Sources:

The Composite Sky: https://www.researchgate.net/publication/375697320_The_Composite

Comments

There are currently no comments, be the first to comment.